![]()

Fire Mapping

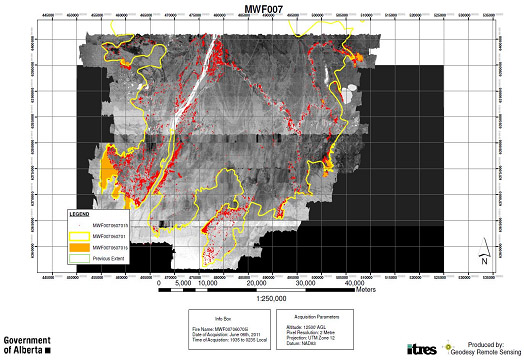

GeodesyGroup and ITRES have teamed up to provide a fire mapping solution for ASRD to use within their wildfire management strategy. Wildfires and hotspots can be imaged from Geodesy’s aircraft using an ITRES TABI-1800 thermal IR sensor. The thermal imagery is then processed to produce thermal maps where active fire, burning areas, and isolated hotspots are evident. From the maps, vector spatial data products are derived. The deliverables are then provided to the ASRD ftp site by the required deadline.Infrared Scanning Equipment

The thermal Infrared sensor that will be used is ITRES’ Thermal Airborne Broadband Imager (TABI-1800).

The TABI-1800 imager has 1800 across-track pixels allowing wide swaths of ground to be imaged with each flightline. TABI-1800 imager has a broad spectral bandwidth that is sensitive to wavelengths between 3700 to 4800 nm. The following tables summarize the main characteristics and specifications of the TABI-1800 sensor system.

The height of the aircraft above ground level determines the across-track ground pixel resolution. Using GeodesyGroup’s aircraft the expected pixel resolution range is 10 cm to 2 m corresponding to 811 ft to 16225 ft above ground. Utilizing the 1800 across-track spatial pixels, this corresponds to a ground swath between 180 m to 3.6 km per flightline. The TABI-1800 is a ‘push-frame’ imager which implies that the along track pixel resolution is not governed by the speed of the aircraft. In other words, the plane can maintain a reasonable survey speed (150 knots is typical) regardless of doing low or high resolution imagery and still acquire square pixels.

Other operational considerations for the TABI-1800 include the weather and environmental conditions in the survey area. While the TABI-1800 can see through most smoke, it cannot image through cloud. Thus, on any given night of operation, the cloud ceiling impacts the height of the plane and the corresponding ground pixel resolution of the imagery.

As the manufacturer of the TABI-1800, ITRES is capable of diagnosing and repairing the system quickly.

Image Capture

The expected operational plan on any given night would be to have one flight with approximately 4 hours of survey time. Of course logistical details can affect the operational plan (airport locations, ferry to site, refueling options near the fires, etc.). The amount of data collected in a flight is not instrument limited; the TABI-1800 has the capacity to collect data for any given flight length.

The TABI-1800 collects frames at a rate of 90 frames / second. This corresponds to approximately 50 GB per hour. The expected survey flights for fire-mapping would be at most 4 hours on line yielding up to 200 GB of data per flight.

Image Processing

Image processing involves three main steps: processing the raw imagery; mosaicking and georeferencing the imagery to produce a seamless thermal map of the survey block; and finally, extracting the necessary GIS spatial vector data products from the thermal map and producing mission summary reports.

The raw TABI-1800 image processing involves correcting for additive signal components and applying calibration files to produce radiometrically corrected temperature files. In addition to the TABI-1800 imagery, the GPS and IMU data (that measures the aircraft position and attitude) from the flight is also processed and blended with the TABI-1800 imagery. Once all raw data is processed and the data streams blended, the flight line files are georeferenced and mosaicked together to produce thermal maps of the survey area. Different survey areas (i.e. different fires) would each have their own mosaic image map produced. The thermal maps are then analyzed and the necessary data products (hotspots, fire perimeters, burning areas, etc) are extracted.

The benefits to the TABI-1800 thermal maps include the high degree of thermal detail due to the TABI-1800’s sensor sensitivity, and the very high spatial accuracy of the resulting map. However, the main processing limitation is the amount of time it takes to complete the processing steps. One reason for this is that the data processing cannot begin until the aircraft has landed. There is no cost effective means to transfer the raw data from the aircraft to the processing stations. However, we are proposing to incorporate some level of data transfer and primary processing in the aircraft. This would allow us to land with some steps in the processing chain already complete. Another factor contributing to our processing time is that the processing software does take time to process the large amounts of image data that is required to make the thermal maps. Our current plan requires approximately four hours of processing time after the flight to generate required deliverables and to upload ASRD.

Digital Elevation Model Data

DEMs are an essential data element for us to create the orthoimage product for this service. Last year we relied predominately on radarsat derived digital elevation models. They are by definition relatively coarse. SRD has available for internal use a variety of elevation data from different sources including high resolution Lidar for specific areas. As part of this proposal we’d ask, when the branch can, they make available DEM data to help provide for a better more accurate deliverable of map information.

Delivery to ASRD

The proposed delivery method for the required data products (imagery, vector spatial data, and summary report) to ASRD is via their ftp site. This will require field access to high-speed internet to enable acceptable transfer rates. If the field base for the ITRES/GeodesyGroup crew for a particular fire is in a location that has reliable high-speed internet, then the field base (i.e. hotel) internet access will probably be sufficient. However, there is no guarantee that the hotel internet will be available on some morning when data delivery is needed. Furthermore, the crew could potentially be stationed in a location where reliable and fast internet is not available.

We propose that our field crews could upload the data with support from ASRD. This could entail ASRD setting up a dedicated secure laptop that would have clearance to connect to the internal ASRD network, and that approved ITRES/GeodesyGroup personal could coordinate with local fire offices to have access to upload the data. This approach ensures the data can be transferred quickly and efficiently on a reliable and fast internal network to ASRD, but at the same time ensuring the security of the internal ASRD computer network.

![]() GeodseyGroup Inc. All Rights Reserved

GeodseyGroup Inc. All Rights Reserved